Choosing A Dynamic Climbing Rope - What Do The Numbers Mean?

Choosing a rope can be a little tricky sometimes. On one hand all climbing ropes sold with CE standards in Australia are good for climbing. On the other hand, anyone who has owned or borrowed a couple different models of ropes knows that they can feel completely different when climbing or belaying. And unlike climbing shoes for instance, where at least you can try them on and use the 'tester' holds in store, you can't really uncoil and climb or belay on a rope then swap it - as it's PPE and not allowed. So understanding a couple numbers on the packaging can really go a long way to getting a good idea as to a ropes properties and how it will handle.

This article discusses the numbers and stats typically displayed on all dynamic climbing rope packagings so you can get a basic understanding and compare them, however it doesn't go into other technology details like core construction, sheath braid and other treatments and technologies. Rope manufacture and indeed rope testing is a dark art and deserves a book written on it so that topic will have to be the subject of another post.

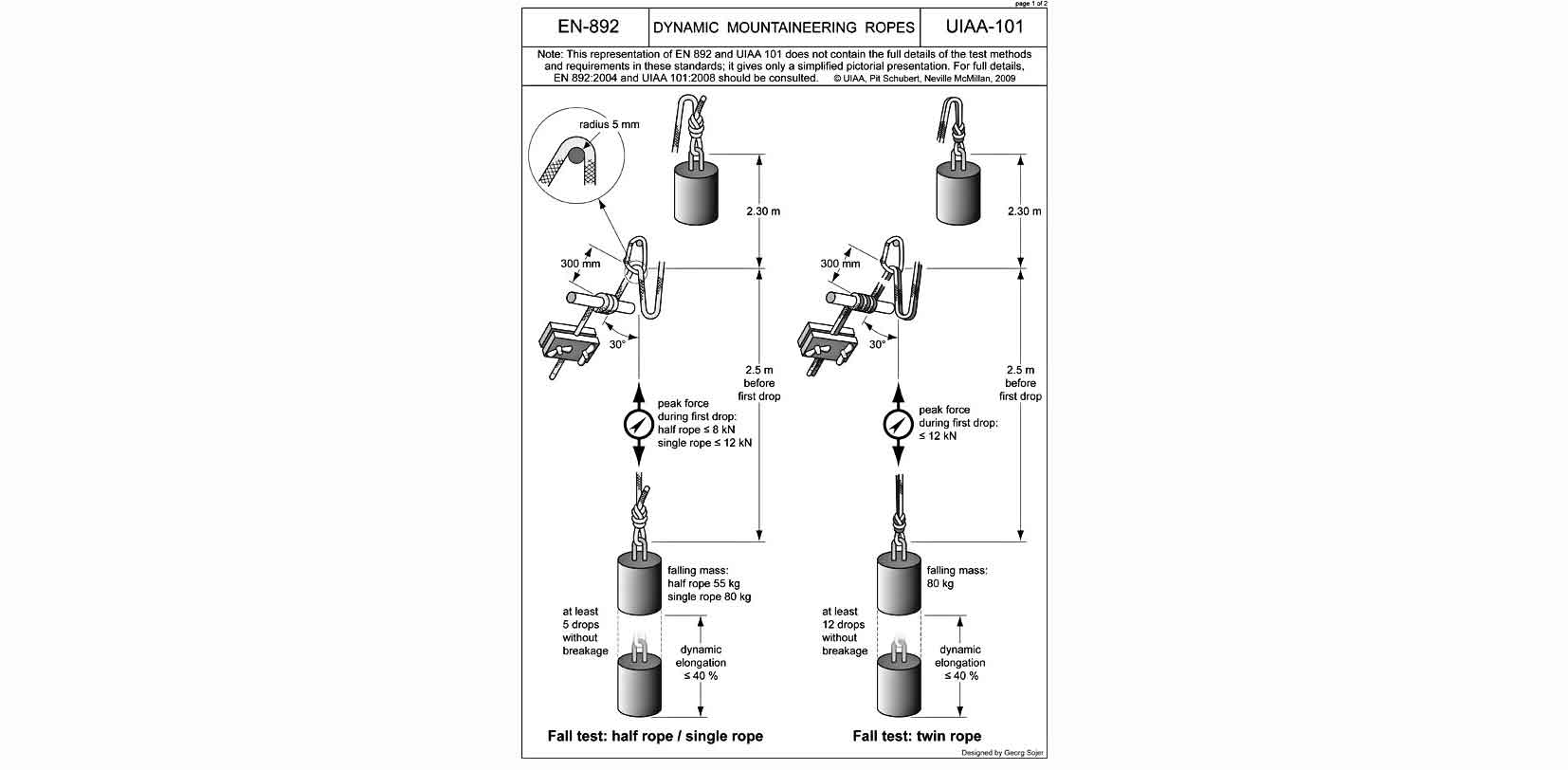

Also before delving into numbers, the other thing to note is that the methods of testing rope attributes - like falls, elongation and even (so one would think) simple things like length and diameter, are designed to be repeatable and consistent. They aren’t necessarily designed to mimic ‘real-world’ use. For example - if one was to buy a new 9.5mm rope and put a micrometer on it and measure the diameter they would probably find it to be thicker than stated. This is because the UIAA diameter test is done under a 10kg load. So again harking back to the intro, these numbers are to be seen as a comparison guide and do help a lot when making decisions but true attributes can only be compared when using the ropes.

Now remember this idea when looking at ropes:

- It is relatively cheap and easy to make a rope that is more hardwearing - But it will feel and act more like a wire cable.

- It is relatively cheap and easy to make a rope that is soft and supple and moves nicely through gear - But it will wear out fairly quick.

- It is hard and expensive to create a rope that has good wear properties and is soft, supple and moves through gear nicely.

This is why you can find such variances in the prices of ropes between different manufacturers and even within the same manufacturer. While a hundred bucks can seem like a lot when you're standing with both feet on the ground in a shop, when you're a long way up ‘wigging out’ on a crux hold trying to make that clip, having a rope that is predictable and easy to handle can make a big difference. A slightly more durable rope that may cost 20% more but last 50% longer can also make a lot of sense. So making the right decision and investing in a good quality rope can make climbing a lot more fun.

Saying all that - what do the stats and numbers on the packaging mean practically in the real world?

Fall Rating

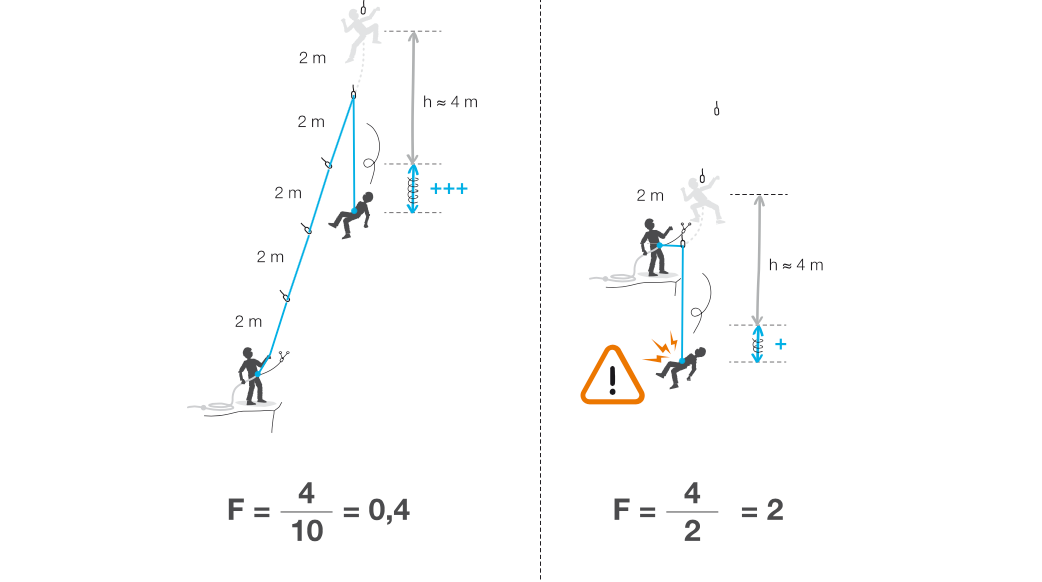

Let's clear this one up straight away - if you're new to climbing you will freak out when you look at the packaging and see "Number of Falls - 6". You will say under your breath "shiver me timbers! This climbing thing is going to get pricy! Six falls then I'm up for a new rope." Well at least that's what I thought when I first started climbing many years ago. The truth however is that the test for this UIAA Fall Rating number is incredibly harsh and if you were to take even one of the falls that are conducted in this test yourself you would be lucky to walk away with your pelvis and future climbing aspirations still intact. In fact, even getting close to half the force of what the UIAA test involves means you're being a pretty gnarly climber (or a dumb one). To briefly explain the test, you need to understand what a fall factor is. The fall factor is a number which equals the length of your fall divided by how much rope is between you ‘the climber’ and the belayer. So for instance if you have climbed up 20 metres (so you have at least 20m of rope out) and you fall 5 metres (some decent air time on a bolted sport route) your fall factor would equal 5/20 = 0.25 . The UIAA test gives fall factor results of nearly 2 - and this in the real world is very hard to do. In fact it can only be done on a multi-pitch climb if the climber were to basically tie off the rope to the anchor with 5m of slack, climb up 5m then fall off resulting in a 10m fall on 5m of rope. Please don't do this. The results will give force ratings of up to 12kN depending on the type and age of your rope and the human body doesn't like forces like that, and internal bleeding and the like can occur well before.

Now, there has been rope manufacturers (usually of the cheaper kind) that design ropes specifically to perform well in this test; to get that number up with the hope of selling more ropes. Apart from these ropes handling terribly they can actually wear out quicker in real world scenarios because they give too much proportion to the core and not enough to the sheath. And the truth is that ropes don't really break - they cut. So almost the biggest factor in having a long lasting rope is the design and thickness of the sheath. As long as you take care not to run your rope over edges or over worn, sharp carabiners, your rope should see hundreds of falls in its life. There is more info on sheaths later but what a lot of people don’t realise is that the UIAA only test single ropes up to 5 falls, as this is the number that passes them as a ‘single climbing rope’. Any number you see above that is a manufacturer claim from their own testing ,and what makes it hard is that some manufactures don’t even bother testing their ropes beyond the UIAA accreditation, they’re happy to stamp the ‘5’ (we passed) on the packaging and move on. All of this is reason for you to look at this packaging, make sure it passes the fall test, and move on!

But now with that out of the way, watch this 7 sec vid of Kevin taking a normal, everyday fall and let's get to some more important numbers...

Rope Category

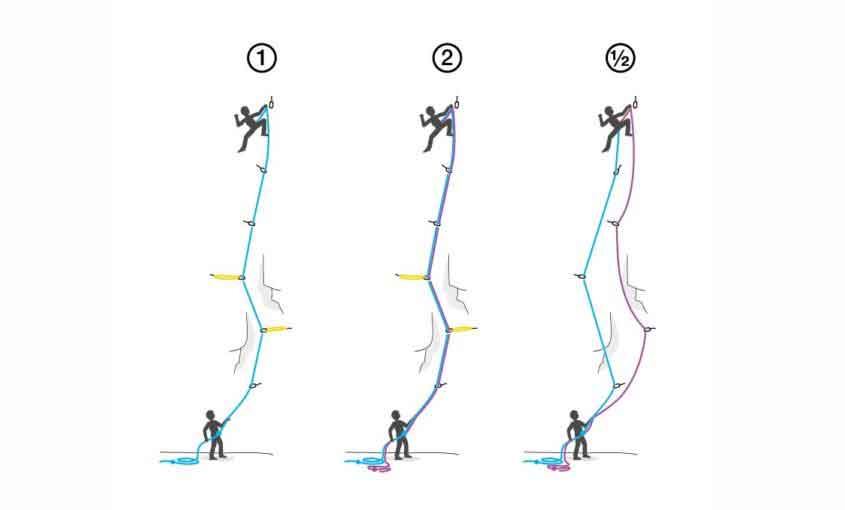

Dynamic climbing ropes are categorised as either single, twin or half. It is important not to use one in the style you would use another, however with technology improving, some ropes are now coming certified as two or even three categories.

Single - Like it sounds, is used on its own and is the most common and simplest rope to use. A lead climber has a single rope attached to themselves and clips it into protection as they climb up. It's important not to double up and use two single ropes as you would double or half ropes as the impact force in a fall, on the top piece of gear and you the climber, can be very high and achieve forces greater than 12kN. As discussed above, this is quite dangerous. Used on its own and correctly, the maximum impact force shouldn't be much higher than 8kN and UIAA require it not to exceed 12kN in worst case scenario (more on impact force later).

Twin - Twin ropes are used almost exactly like a single rope but you are clipping two ropes together into every piece of gear. Why would you use them then? For two main reasons - it allows you to abseil twice as far as a single when getting off routes and on long approaches you can share the load with your partner. For these reasons they are a favoured by alpinists and ice climbers. When using two strands together UIAA require forces not to exceed 12kN, however you wouldn't use these on their own as they would elongate too much when fallen on as a single rope.

Half - Half ropes are the most complex to use, both for climber and belayer, but also have some key benefits. You climb with both ropes attached but clip one rope only into each piece of gear. This system is particularly beneficial when trad climbing or climbing long wandering pitches as it dramatically reduces rope drag. It also can reduce the impact force on single pieces of gear, instead spreading the load over a couple of pieces, which can be good for marginal trad placements. They, like twin ropes have the benefit of being able to rappel the full length of one of the ropes. UIAA require a maximum of 8kN impact force for each half rope

Diameter

After the rope's category, the diameter of the rope is perhaps the most important number in determining the style and use of a rope. The diameter will have a lot of influence over most of the rest of stats listed below like impact force, elongation and weight. It will also have influence over other important things that can't be measured like how well the rope moves through gear and how long it will last. There are three main categories of single rope diameters -

- 10.1mm + are long lasting, burly ropes. Good if your main requirement is longevity.

- 9.7mm - 10mm are general "all-rounders", they sit in the middle and are either the performance end of the burly ropes or the burly end of the performance ropes. If you don't know what you want - probably look at something in this range. They are reasonably light and will flow through belay devices and gear well while still being able to take a bit of abuse. They can be used for pretty much all styles of climbing.

- 8.9mm - 9.6mm are the lightweight performance end of single ropes. Like most high-end products, don't expect them to last as long as their heavy friends but the benefits can be worth it. When sending long hard climbs, weight differences of even 5 grams per metre are noticeable once you are 30m up. Not just because of the weight savings, but because of the reduced drag running through gear. So a lightweight 9mm rope feels completely different on a long lead compared to a 10mm. It's also worth noting down the skinny end of ropes that belaying, and in particular braking a fall or an abseil, can be more difficult. I'd recommend using an assisted braking device like an Edelrid Megajul or Petzl GriGri on ropes skinnier than 9.5mm.

The same rules about diameters apply to half and twin ropes although they're both thinner respectfully. Half ropes generally run from 8-8.9mm and twins from 7-8.5mm. Although all rope categories are gradually getting thinner as technology improves.

Impact Force

Climbing ropes are dynamic, the reason they are dynamic is that when falling, you need a big elastic band to absorb a lot of force. This is important for you and the gear or hardware in the rock. Think of the difference between going bungee jumping with a wire cable and going with a bungee cord. Same body weight, same jump, one rips your legs off and pulls the bridge down, the other is soft like pillows. The trick with climbing ropes however is that impact force is directly related to how much the rope elongates (or stretches). So having a soft catch is great but you don't want a climbing rope to elongate too much otherwise you will likely hit ledges or the ground. Generally speaking, if you are top-roping or not really taking any falls, having a higher impact force isn't really a problem. If you’re climbing on long, over-hung routes and taking 10m falls, having a lower impact force will be much kinder on your body and gear. A lower impact force is also good if you like climbing sketchy trad lines with marginal placements as there will be less force on your top piece of gear when you take a fall.

Static Elongation

Static elongation is how much stretch the rope has when an 80kg weight is statically placed on it and is given as a percentage of the ropes length. It is mainly important when you think about either top-roping or "working" a route on lead. If the rope has a large static elongation, then when you're trying to work moves on a climb you will constantly sag below the holds that the belayer is trying to hold you at. For people seconding or top-roping, it means that even if the belayer keeps the rope taught, the climber will fall (albeit gently) down a little if they let go. UIAA demand single dynamic climbing ropes not exceed 10% as this can become dangerous for hitting ledges or the ground when on route.

Dynamic Elongation

Dynamic elongation is how much the rope will stretch with an 80kg weight dynamically falling on it on the first fall of the drop test. As discussed above, the UIAA drop test, nearly reaches a fall factor of 2 so is not really transferrable straight to real world scenarios. Typically climbing ropes sit around 25-35% dynamic elongation and this number is very closely related to the maximum impact force. The longer the stretch, the lower the impact force. This is a good thing but it is also worth keeping in mind when falling close to the ground or a ledge. If you buy a rope with a large dynamic elongation, make sure the belayer is vigilant about keeping the climber short of ledges when falling.

Sheath Proportion

This is displayed as a percentage and will show you the thickness of the ropes sheath. Kernmantel dynamic climbing ropes are constructed with a core and a sheath. This statistic is not always shown on climbing rope packages but quick searches or a look in the catalogue can usually find it. Harking right back to the first point on fall factor, to make a rope that performs well in the UIAA fall test, you would actually want to beef up the core of the rope and reduce the sheath. However in real world scenarios it is nearly always the sheath of the rope that is damaged and forces you to retire it, either by abrasion or cutting. So in fact, to make a more durable "real world" climbing rope, manufactures put a higher percentage of the rope in the sheath. The flip-side to this coin however is that ropes become stiffer and more cable-like, so you wouldn't want it too high. Manufacturers are always searching for ways to braid and treat the sheath in different ways to up its proportion as well as its suppleness - and this is where the art of making a climbing rope really is, and separates the good from the bad.

Grams Per Metre

I'm sure you can work this out for yourself - the weight of your rope. Even though the differences might not seem like much, on long pitches the difference of a few grams can add up. If you are looking for every marginal gain you can get to send that next king line then this number and the diameter may be the most important properties for you.

Like the UIAA diameter test mentioned earlier, the weight test is not as straight forward as one might think and often if you were to measure a brand new 60m rope and divide the weight by 60 you’ll get a higher reading. The important thing to remember though is that their (the UIAA) test is designed to be consistent across all ropes so it is a fair comparison in shop.

Length

Generally in Australian climbing and most of the places around the world a 60m rope will suffice. This is because most single pitch climbs are 30m or less and most "multi-pitch" pitches won't be much more than 50m. This makes a 60m rope convenient because on a 30m pitch the climber can easily be lowered to the ground. Occasionally in the Blue Mountains you come across 35 and 40m pitches but with a little care, a knot in the end and a little static rope elongation ;-) one can reach the ground.

There are a couple places around the world though, that longer single pitches are becoming popular. This is mainly in Oliana Spain and Ceuse France where single pitches can reach 50m. I would make the point and say that this is quite unique to these crags and you can still climb at them with a standard rope, you just need to re-thread when lowering, I certainly wouldn't be special ordering a 100m rope if the thought of an Oliana climbing trip is just a twinkle in your eye. Coiling that 100m rope and carting it in and out of Shipley every weekend would be a pain in the bum.

The reason why you might invest in a little extra and get a 70m comes because of longevity. When you wear out the ends of your rope you can cut them off and you've still got a 60m rope. Do that too many times to a 60 and you'll be getting quite short.

Now while all these numbers and categories don't tell you the quality and handling of the rope directly, knowing how they work can give you a fairly good idea of a ropes characteristics. When you've owned a rope or two it becomes very easy to pick your next weapon of choice based on comparing it to the numbers of your last one.

Right, enough reading, now get out there and climb a rock!

To read more about the official UIAA Testing Procedures and Standards For Dynamic Climbing and Mountaineering Rope Click HERE

Here are some other great resources on rope manufactures